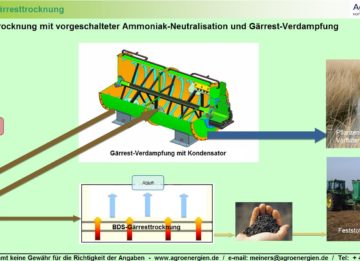

BDS-evaporator digestate dryer as heat utilisation concept at a renewable resource biogas plant with 20,000 tons of digestate.

The recommended heat utilisation concept emanates from a preferable maximum utilisation of the available heat of the two CHP units with 566kWth (amount = 1,132kWth). In order to improve efficiency, the heat is used on two levels.

Level 1:

The two digestate evaporators receive the complete amount of waste heat of both CHP units with a supply temperature of 85-90°C of two heat exchangers.